BY : MALACCA BRANCH ISSUE : NOVEMBER 2012

Saturday, December 22, 2012

Wednesday, December 12, 2012

Monday, December 3, 2012

Thursday, November 22, 2012

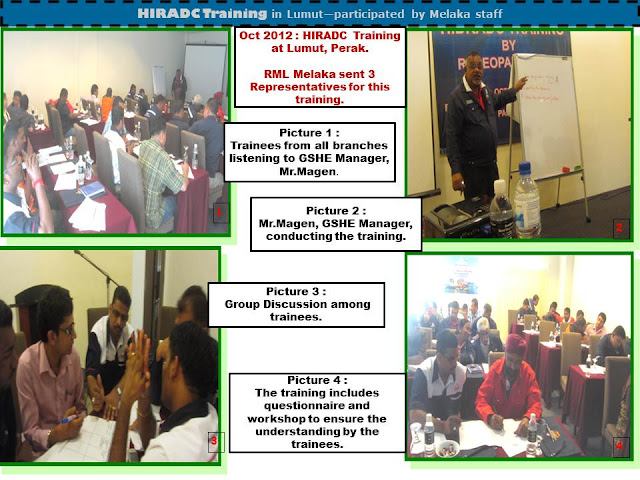

HIRARC WORKSHOP AND PREPARATION TRAINING AT LUMUT

By: Magendren. R

GSHE

Manager

HIRARC or

HIRADC is used as a structured approach in Leopad Group for identifying,

evaluating and controlling hazards at workplace. This is to achieve better the company

performance of no injury/ damage to employees, properties, environment and

reputation. Ever since the achievement

of OHSAS 18001 & MS 1722 certifications, our own HIRARC has been able to

ascertain the extent of compliance and influence on the company’s performance,

that includes reduced accident/ incident rate, improved safety practices,

enhanced standards and increased profitability.

Visible top management and employees commitment to risk assessment,

competitive safety intelligence, high level safety knowledge and cooperating in

safety resources are the means of sustaining safety best practices in Leopad

Group.

In line with

the continual improvement in the management of risk control, a one day HIRARC

Workshop and Preparation training was conducted at Best Western Marina

Island Resort Lumut on 6th October 2012, sponsored by RM Leopad

Lumut Branch. This training was conducted

to ensure participants understand the risks and control measures to be taken in

their job scopes, and also to be able to prepare their own HIRARC. Group SHE Management is very positive that

the participants are now able to understand the requirement and the true values

of HIRARC. They should now be able to

perform and lead their subordinates towards an Occupational Safe and Healthy

working culture.

HIRARC WORKSHOP

Saturday, September 22, 2012

Saturday, September 15, 2012

Friday, September 7, 2012

HSE – FINDINGS and TRACKING

BY: MAGENDREN. R ISSUE : SEPTEMBER, 2012

GROUP SHE MANAGER

Leopad Group commitment to employees safety and health is our highest company

value, and our Top Management and employees involvement has been the foundation

of our success in our improved performance over the last few years. From our

Top Management to our line supervisors, visible and consistent commitment to

safety and health has made a significant impact. We have taken on increased

responsibility and accountability in Safety and Health, and our journey to an accident

or incident free workplace is a continuous one.

One measure we use to monitor our Safety

and Health performance, compliance to

regulatory and the company’s requirements, is by conducting frequent workplace audits.

Our standard requires that all incidents be reported, recorded and

investigated, based on the type and severity of the incident. Root causes must be identified and action

taken to prevent recurrence. Our Safety

and Health Management System enables us to report incidents, track the progress of

corrective actions, analyze the trends and identify potential risks to Safety and Health. A tracking format is now implemented and practiced ( see below).

We collect and analyze

information on:

- -

Unsafe acts

-

- Unsafe conditions

-

- PPE non-compliance

-

- Near miss

-

- Scaffold Standards

-

- Equipment /Hand Tools

-

- Material Conditions

- Housekeeping

Subscribe to:

Comments (Atom)

Happy Deepavali

The festival of light is here! May you be the happiest and may love be always with you. Happy Deepavali!

-

T he inspection of plant and pipework for CUI can be extremely expensive if all insulation material has to be removed. Often windows a...

-

We already know that an oil or petroleum refinery is a place where natural, raw oil is processed into refined products like petroleum, g...